Chinese scientists have successfully boosted the efficiency of a new generation solar cell to 28% in a race with foreign rivals who achieved the result in December 2018 and have since pushed that level to 33.2% in April this year.

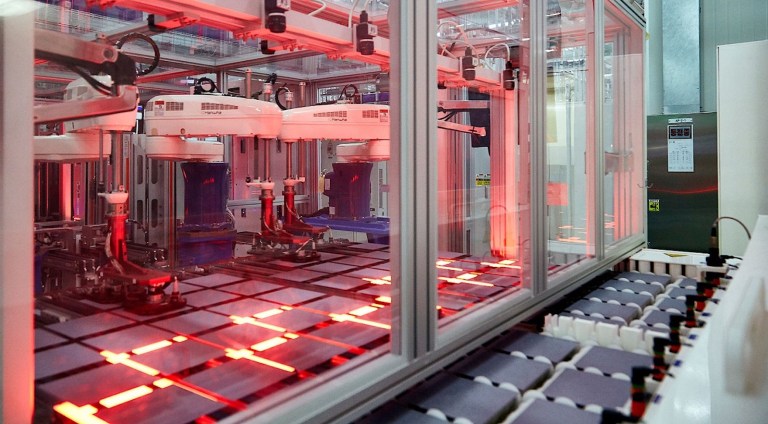

Not waiting for solar perfection, some Chinese firms, including a company established by China’s leading researcher, already have gone into production of perovskite and silicon tandem solar cells (PSC).

This so-called third-generation solar cell is said to be able to convert 50-75% more sunlight into electricity than the traditional silicon photovoltaic (PV) cell.

The product is also 95% cheaper than the silicon solar cell as its key raw material is methylammonium lead iodide, making it a potential great option for countries that want to switch to solar power to meet their carbon neutrality targets.

Tan Hairen, a professor at Nanjing University’s College of Engineering and Applied Sciences, and his team announced their PSC technology “breakthroughs” in an article published by Nature, a London-based weekly scientific journal, on June 8.

According to the article, Tan’s team has achieved an efficiency of 28%, which means 28 out of 100 units of incoming sunlight can be converted into electricity, on a research-sized PSC of 0.49 square centimeters.

In January 2022, the team achieved 26.4%. At that time, it also recorded an efficiency of 24.2% on a larger PSC (1.04 square cms) and 21.7% on a mini-module-sized one (20.25 square cms). The bigger the size of a solar cell, the lower the rate of efficiency it can achieve.

Tan had said in a previous interview that during the research his team had considered different factors including the production and material costs.

He also said his Renshine Solar company started making PSC modules with efficiency ratings of 18% in February. He said such a product is commercially viable as it has an output equivalent to that of a traditional silicon solar cell with 20% efficiency.

By comparison, the most efficient silicon solar panels currently available in the markets have an efficiency of 22.8%. Most panels are only 15 to 20% efficient.

In May last year, the United States Department of Energy’s National Renewable Energy Laboratory (NREL) created a silicon solar cell with a record 39.5% efficiency, though it is not yet commercially available.

In terms of research-sized PSCs, many scientists in the world have already entered the club of 30% efficiency. The United Kingdom’s Oxford PV had set world records at 28% in December 2018 and 29.52% in December 2020.

A team at Helmholtz Zentrum Berlin (HZB) in Germany achieved 29.8% in November 2021 and 32.5% last December. On April 16, researchers at King Abdullah University of Science and Technology (KAUST) in Saudi Arabia achieved 33.2%, which remains the world record so far.

The Duong, a researcher at Australian National University (ANU), which recorded a 30.3% efficiency in February this year, said it is important to surpass the 30% mark as that is considered a threshold for the commercialization of tandem technology.

Build it and they will come

The ANU cells have not gone into production. Duong said mass production of PSCs will be practical by 2026.

Some firms, however, Renshine being an example, prefer to go for commercialization – even if on a very small scale – as early as possible to secure a first mover advantage.

Last month, Oxford PV set a world record of 28.6% efficiency on a commercial-sized PSC (258.15 square cams) known as M4.

Seoul-based solar manufacturer Hanwha Qcells, partnered with the HZB, also announced last month that it would invest US$100 million to build a pilot tandem-cell production line in Jincheon, South Korea. The factory will commence mass production by 2026. Without disclosing the size, Qcells said its PSC has a 29.3% efficiency.

Duan Xiaohu, an analyst at East Asia Qianhai Securities Co Ltd, published a research report in March saying that some Chinese solar panel makers, including GDL Power, MicroQuanta and Utmolight, have started making PSCs, although their products may have short life spans and low efficiency.

“Methylammonium lead iodide, the most common raw material of PSCs, has a low stability, which may result in a short life span of the solar cells,” Duan says in the report. “Besides, there are usually more defects on larger PSCs, meaning that it is difficult to produce a large solar cell while maintaining high efficiency.”

Last July, MicroQuanta delivered a batch of 5,000 units of its PSCs to a power station in Zhejiang for a trial run. Media reports said the company achieved efficiency of 21.8% on a PSC with a size of 19.35 square centimeters.

Read: China’s fastest yet quantum computer still way behind US

Follow Jeff Pao on Twitter at @jeffpao3