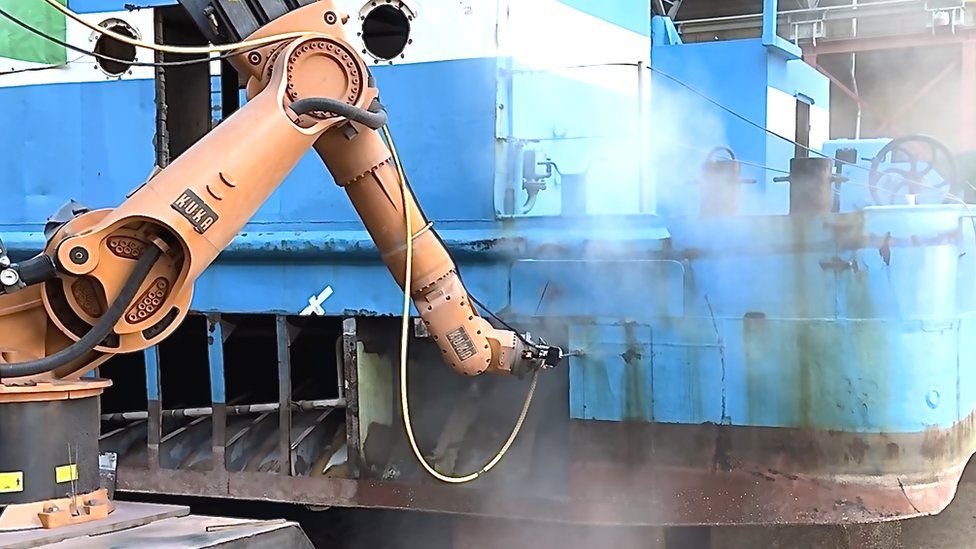

A massive mechanical arm swings into activity while brandishing a waterjet that can pierce material.

It is dissecting a sizable ship’s ship. The building quickly gives way to the cutting plane despite having withstood the sea’s power for decades. The machine will soon have cut out a sizable square of material.

The system softly advances to the following section after completing its task.

According to Bryce Lawrence, operations manager at Leviathan,” you can have computers starting at the arrow and the harsh, and two points in the middle, working towards each other.” The German-based company intends to disassemble large ships using a group of robots so that the material can be recycled.

Mammoth ships frequently end up on a heavily polluted beach anywhere in South Asia when they retire from decades of transporting goods such as consumer products or fuel between continents. Workers it skillfully disassemble the ships using torches powered by fossil fuel. Safe attire is hard to come by. Death is no.

Leviathan and other businesses are looking for ways to complete this job in a much cleaner and safer manner. However, there are no assurances that they will be able to compete with South Asia’s dirt-cheap miles.

We’re very, very small carbon when it comes to ship recycling, according to Mr. Lawrence, who also explains how collected steel may be transported to mills all over Europe on electrified trains at Leviathan’s Stralsund facility on the Atlantic coast of Germany. He continues,” Business functions are anticipated to begin in the upcoming times.”

The company’s prototype system is a combination of well-established technology. The waterjet is produced by ANT AG, another European company, and the machine wings are the kind that toil in auto factories, for instance.

Bomb disposal specialists use this exact technology to cut the fuses out of bombs because it blasts a mixture of water and sand at large pressures.

The general manager of ANT AG, Till Weber, advises that someone view the weapon, activate the controlling system, and then move as far away as they can. Thankfully, in these circumstances, the flight may be operated from a half-kilometer away. According to Mr. Weber, it is already in use in Ukraine.

Mr. Lawrence contends that such a program may one day finish the job much more quickly because it employs significantly fewer workers than conventional shipbreaking does. Leviathan is developing computer software that will automatically program how to hack up a vessel as effectively as possible.

On the other hand, all of this comes at a cost, and the machine arms must be mounted correctly on specialized machines that are attached to clean docks. They cannot simply be dumped on a shore.

He describes the waterjet-based system in Germany as having a” encouraging stop.” He does, however, point out that it is also important to manage substances in the water used to cut up ships.

According to Mr. Lawrence, a isolation area may be located at the Stralsund facility to catch harmful materials and jet water that have been blown off the ships. This liquid can be reused for more cutting after being thoroughly decontaminated.

The Dutch-based Elegant Exit Company also claims to be able to properly disassemble ships. It started recycling the 160m-long box vehicle Wan Hai 165 earlier this year.

At its Bahrain service, the company uses gas-fueled cutters, but it claims to remove hazardous materials before turning boats into large pieces of metal, up to 25 tons, for vehicles.

A spokeswoman says,” We de-Loke a ship ,” explaining that the plan is to safely disassemble each vessel separately. In the future, the company will assess mechanical, plasma, and waterjet mechanical cutters.

According to Ingvild Jenssen, the founder and director of the non-governmental firm Shipbreaking Platform, reuse ships has been a filthy business for far too long.

The fact that the entire freight industry is aware of the issues is even more surprising, she continues.

Since then, two of the buildings have been dismantled at an EU-approved gardens in Turkey. According to Colin Morrow of Sepa,” The second equipment, Ocean Princess,” has not yet been disassembled and recovered because it was only exported to Turkey in May 2023.

According to Ms. Jenssen, better records of the toxic materials contained in a vessel was aid recyclers in properly processing it.

The University of Maryland’s Kuishuang Feng concurs and adds that shipowners may also be subject to a tax when purchasing an item that is redeemable if it is eventually recycled properly.

- The gentle and slow plane conducting detective missions

- Competition between the US and China drives investment in space technology

- Computers are taught how to restore coastal islands.

- How longer until your meals are being done by a machine?

- The turbo-charged species that might increase farm productivity

The late ratified Hong Kong Convention, according to Mr. Feng and Ms. Jenssen, does not go far enough to ensure the sustainability of shipbreaking. The International Maritime Organization’s representative, but, contends that the agreement will lessen the negative effects of ship recycling on the environment.

High-tech alternatives might have an impact. Mr. Lawrence asserts that Leviathan would only permit this in secure, controlled environments with the same capacity for capturing toxic substances as he claims is present at Stralsund, but that the company hopes to permit its system to different shipbreaking yards.

According to Jenssen, the condition in some South Asian miles is still one of” regular exploitation.” ” You have employees who commute to work but don’t return back.”