The following article was written for Asia Times by Robert Hargraves, a cofounder of the company ThorCon, which has scaled up technology pioneered by US Oak Ridge National Laboratory to design the government-supported plant.

The safety properties of the molten salt reactor design that ThorCon is using are well-known, and it is credible that those features make running the reactor easier. (- Jonathan Tennenbaum, science editor)

The distorted map below illustrates the world’s nations, not by area, but by population. Indonesia (in green) uses only a seventh of the per capita energy the US does, and India even less. Will CO2 emissions rise as such populous nations develop?

Wealthy United States and Europe, which consume energy by burning fuels and emitting CO2, now want to reduce their emissions. They import energy-intensive products from developing nations such as Indonesia, increasing those nations’ needs for energy and electric power.

Burning fuels for energy increases those nations’ CO2 emissions. Perversely, Europe is starting to tax exports from these nations proportionate to the CO2 emitted in manufacturing.

People in these populous nations aspire to the living standards of the rich US and EU nations. They will use more energy and especially electricity to build their economies, trade competitively with rich nations and increase citizens’ incomes. For them to reach European standards, world electricity consumption must double.

Energy for economic development

The emerging economies build coal-fired and liquified natural gas (LNG)-fired power plants because these are the least expensive ways to generate full-time, reliable electricity for commerce and industry. They need to optimize scarce capital to power up their economies.

To reduce global CO2 emissions, we must incentivize developing nations to choose electric power sources that emit little CO2. But at present coal-fired generation is the cheapest option for them.

Advocates claim wind and solar power generation is cheaper. But that has not worked out, in practice, simply because those energy sources are dispersed and intermittent. Wind is not strong in equatorial Indonesia. Solar panels produce intermittent daytime energy and no nighttime energy.

It’s not possible to run industries such as mining or smelting or chemical manufacturing with intermittent energy. These activities require continuous power, at levels that batteries can not provide.

Grid-scale batteries cost US$500 for capacity to store each kilowatt hour of electric energy, typically generated for about $0.03 to $0.10. Google abandoned its RE<C project in 2011, concluding renewable energy could not economically replace coal.

Like Iceland, Indonesia has some limited opportunities for dispatchable geothermal energy because it sits on a geologic “ring of fire.” Geothermal power contributes about 3% of Indonesia’s total generation capacity of 62 GW.

Hydroelectric power might provide continuous, dispatchable power service, as it does in Brazil, Quebec and Scandinavia, but worldwide sites for suitable dams have largely been exploited – and droughts stop generation altogether.

Indonesia’s per capita electric power consumption is 114 watts, while Europe’s is 780 watts, about seven times as much. This suggests Indonesia’s 274 million people’s future average demand may rise to 200 GW, requiring at least 250 GW of generation capacity.

Nuclear power can provide full-time, dispatchable, CO2-emission-free power, but there are no nuclear power plants in Indonesia, yet. Nuclear power is the only realistic solution to energy poverty and economic growth with zero CO2.

Uranium is a million times more energy-dense than coal, so in physical terms, uranium energy ought to be cheaper than coal energy. Unfortunately, nuclear power has up to now been more expensive.

If nuclear power is to provide an answer, the cost of nuclear-produced electricity must be drastically reduced. Otherwise, there will be no economic motivation for nations to satisfy their increasing energy needs without burning coal or LNG.

How can we reduce the capital costs and electricity costs of nuclear power?

ThorCon

In 2013 the American engineer Jack Devanney initiated the ThorCon project with the aim of mass-producing nuclear power plants that can generate electricity at a cost below that of burning coal. ThorCon company has remained steadfastly committed to this goal.

Devanney was a professor of ocean engineering at MIT and worked as well with the US Navy shipbuilding program. He learned that the Navy’s paperwork bureaucracy produced faulty ships, years late, with billion-dollar cost overruns.

As demand for oil and thus for tanker ships grew, shipyards in East Asia competed internationally on ship quality and cost. They cut labor costs to five labor hours per ton of fabricated steel, built machinery for automated cutting and welding of steel plates and prefabricated component blocks up to 600 tons. Ships were assembled in less than a year, and mass-produced in dockyards at low, competitive costs.

Devanney used this manufacturing capability to design and build eight supertankers for Loews Corporation, including four of what at the time were the world’s largest supertankers.

To significantly reduce world CO2 emissions requires mass producing tens of CO2-free nuclear power plants each year rather than tens of new coal and LNG-fired plants.

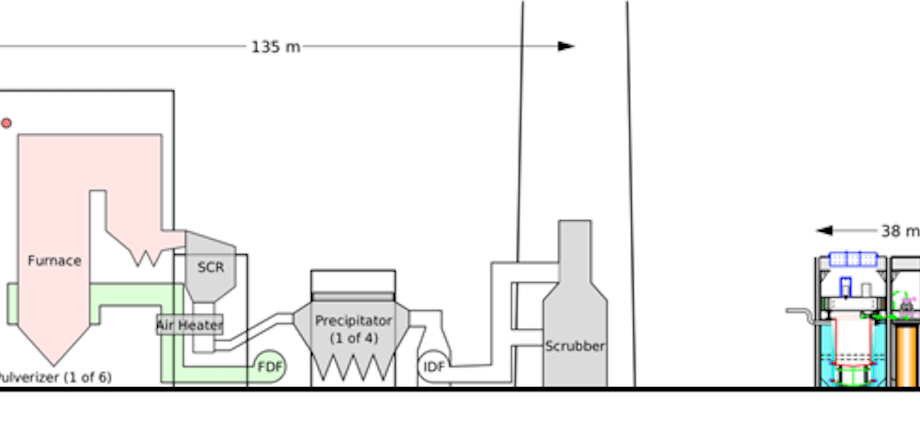

The ThorCon company has developed a 500 MW nuclear power plant design, ThorCon 500, that is suitable to be mass-produced in competitive factories – shipyards. The world’s largest shipyard can produce 2 million tons of steel ships per year. That’s enough steel fabrication capacity to make 20 GW of ThorCon 500 power plants per year.

Present plans foresee a prototype ThorCon 500 power plant to begin test operation in 2028.

Low-cost design

Shipyard docks are wide enough to build 65-meter beam vessels, setting the ThorCon 500 plant width. The steam heat source is two molten salt fission reactors, generating 557 MW (thermal) each. Efficient supercritical steam turbine generators benefit from economy of scale, so a single 500 MW (electric) turbine generator is less costly than two smaller ones

The uranium fuel is dissolved in molten fluoride salts of sodium and beryllium, which are continuously circulated through the reactor and heat exchanger. The high-temperature (704°C) heat of the molten salt exiting the reactor is converted to 550°C supercritical steam.

Thereby a ThorCon 500 power plant generates nearly 50% more electricity from the same amount of uranium than do current pressurized water nuclear reactors with their more massive, lower-temperature steam turbines.

ThorCon 500 also reduces costs by using 100% passive safety, not requiring staff of highly trained operators. In a total electric blackout, overheat or other failure, the reactor shuts down and cools itself without operating any valves or pumps, relying only on gravity and thermodynamics. Operators do not have to take any action to bring the plant into a safe state. Indeed, operators cannot do anything to deviate the plant from a safe state.

ThorCon 500 uses the same, commercially available turbine-generators as a coal plant. But while a coal plant of comparable electric output consumes 5000-10 000 tons of fuel every day, ThorCon 500 needs on average only about 15 kilograms of its uranium fuel.

The ThorCon 500 is designed to help developing nations grow reliable electric power grids. New power plants can be ordered and connected within two years of completing site selection and all permits.

A waterside site with a water depth of 5-10 meters is prepared and the grid connection is built. With advance planning for the turbine generator, a shipyard can build the ThorCon 500 plant in less than one year. It will be towed across the ocean to the site, ballasted down firmly to the seabed, and then connected to the grid.

Developing nations’ grids may be subject to interruptions by transmission faults or fading intermittent power sources. A ThorCon 500 can load-follow, changing compensating power generation by 5% per minute.

It also has “blackstart” capability, meaning that it does not require electric power from the grid to start up. In the event of a regional grid collapse, a ThorCon 500 can provide the initial grid power needed by other generators to restart.

Powering Indonesia

Indonesia has about 40 GW of operational coal-fired power plants, with 19 GW under construction.

At the 2022 G20 Summit in Bali, a group of governments issued a joint statement noting that they would work to mobilize $20 billion for the “Just Energy Transition Partnership” (JETP) for Indonesia. The JETP aims to shut down Indonesia’s coal power plants and replace them with renewable energy sources.

But Indonesia has not agreed, because funding is absent and because wind and solar sources cannot power growing industries such as mining and smelting. Indonesia produced 1.6 million tons of nickel in 2021 to meet growing world battery demand, requiring 10 GW of electric power.

Such industries are now planning their own 13 GW of captive, dedicated power plants to keep them from relying solely on the government-owned utility Perusahaan Listrik Negara (PLN).

The viable alternative is for ThorCon to build nuclear power plants with private funds and sell full-time electric power under contract to PLN at prices cheaper than coal-produced power. Multilateral development banks such as the World Bank and Asian Development Bank refuse to finance nuclear power plants.

But the low capital cost of ThorCon 500, at $1 per watt of electricity generation capacity, can be attractive to private investors.

In 2022, the governor of Bangka-Belitung province recommended Kelasa Island for the ThorCon prototype. PLN Engineering analyzed the uninhabited island harbor, routes for an undersea power cable and the impact of interconnection to the electric grid serving Bangka-Belitung and Sumatra.

ThorCon has engaged nuclear-experienced Agrupados Empresarios to help complete the detailed design and prepare permit applications to Bapeten, Indonesia’s nuclear regulator. Because the ThorCon 500 is a vessel to be towed across the seas, Bureau Veritas provides inspection and certification services to comply with international rules.

In March 2023 ThorCon and nuclear regulator Bapeten began formal pre-licensing consultation about the design and safety of the power plant in regular meetings. The prototype ThorCon 500 power plant is expected to be operating under test at Kelasa Island in 2028.

After earning design approval from Bapeten in 2030, ThorCon and Indonesia are planning more such power plants. Subsequently, ThorCon hopes to build 20 500 MW power plants per year.