A little outside scoop: Members of the parliamentary team accountable for drafting the CHIPS Act visited a US alliance in East Asia with a sizable domestic semiconductor industry in the early stages of the legislation.

The mind of the semiconductor industry connection of that region, along with several government officials, expressed censure on a dozen aspects of the program during a shut- door session.

One criticism, however, was particularly vocal: The Chinese are attempting to monopolize the market for older nodes ( 25 nm and above ), but the CHIPS Act does not address this. The stated objective of the plan is for the United States to have complete control over the device supply chain.

The Chinese may occupy 50 % of the less sophisticated device industry by 2030 and by this reality alone, the United States may lose out on the supply chain power that it is aiming for.  ,

Although the CHIPS Act is not a bad idea, it is an excellent start, but it is insufficient if our goal is to control chip production. We are funding companies that are investing heavily in profitable chips, yet our vulnerability concerning lower- tech, yet equally critical chips, persists.

These chips make up the foundation of essential everyday items like military hardware, cars, planes, and medical equipment.

The Chinese are using the same economic strategy as they have repeatedly, but with a stronger ferocity and a more deliberate geopolitical angle, namely, to find a weak point in an industry, dominate the low-end, and then advance.

Their foundries, namely SMIC, the Chinese TSMC rival, are manufacturing the low- tech chips, before taking aim at more advanced nodes. The only difference is that China views semiconductors as a strategic benefit.

They have made it clear that having a strategic chokehold on these low-end chips gives them an advantage in economic conflict with the US in addition to the crucial domestic self-sufficiency.  ,

Although the US did this, it has proved to be insufficient. The government has not effectively provided the incentives recipients of the CHIPS Act grants. Meanwhile, the Chinese are moving full steam ahead with their plan.  ,

The loss of control over higher node chips will not only compromise our consumer goods supply chain but pose a far more severe threat to our military supply chain. We already have insufficient control over chip provenance in military applications, and the situation is getting worse.

For instance, a military Humvee requires thousands of chips, from GPS to sensors to CPUs. The most advanced processor in a military device might use 14nm technology—equivalent to what an iPhone used in 2015—with most being far less sophisticated.

Losing control of our ability to produce essential military hardware means losing control over our supply chain for these less developed chips.

We do n’t employ either a defensive or an offensive strategy. And we need both. Even if it is unprofitable, our defensive strategy should be to force businesses that receive government funding for manufacturing to allocate to more mature nodes.

We need stricter sanctions and tariffs to stop the Chinese from being as offensive as possible.  ,

context of technology and business

As American as apple pie, the semiconductor industry. We started it. In many ways, we continue to have a dominant position in it. The majority of the major players in the sector are American.  ,

And we do still hold a vehement majority in a few crucial areas that are not going away in a while. We design the majority of the world’s chips, or about 70 % of the chips, in terms of market share.

And we control the major tools and associated technologies, both physical tools ( with the exception of ASML) and digital tools, like Cadence and Synopsys.  ,

Only in chip manufacturing has our position slid. It was a broad-based decision to outsource fabrication to foundries. A “foundry” serves as a contract manufacturer available to all for chip production, while a “fab” refers to any semiconductor manufacturing facility.

There are US fabs in the mix still, but we have primarily outsourced to foundries overseas like TSMC and UMC, both Taiwanese. The majority of our foundries only produce chips for the business that owns them.

We now desperately need an independent semiconductor supply chain, especially given Taiwan’s increasingly fragile position, which requires it.  ,

Chris Miller, author of” Chip Wars,” has written a detailed historical account of how American semiconductor companies transitioned from having their own factories to being fabless for more information.  ,

The primary reason for outsourcing chip fabrication is straightforward: it is immensely capital- intensive and often less profitable.

Node sizes have also been mentioned before. What does this phrase actually mean? Essentially, it means very little. Essentially,” Node size” is a marketing term. For our discussion, it refers to a generation of technology and a “process” —a group of tools, methods, and machinery that collectively create transistors with specific speeds and power consumption levels.

Smaller node sizes correspond to higher performance. The most cutting-edge GPUs and CPUs, which frequently appear in news stories, demand surprisingly small node sizes. Having said that, the majority of the chips that allow for contemporary technologies have larger nodes and are less computationally intensive.  ,

Let’s examine some of the chips inside a more advanced air-to-air missile, and we can see why these higher node, less developed chips are so fundamental.

- The radar system: These communication devices are required to receive targeting signals, also known as front-end components, which include multiple chips. While some of those chips within a single component might be extremely complex and high speed ( including advanced materials, which are hard to fabricate ), other simple chips like PLLs, which stabilize the signal, are fine to be at 65nm.  ,

- Engine and propulsion systems: Again, we might see two chips or a combined chip here. Engines require continuous heat sensors and control systems to adjust the engine operation. On a single chip, one might have a heat sensor and a microcontroller, but quite frequently one separates them. These are frequently 90 to 180 nm in length, which is not a reason why they need to be low on nodes.  ,

The most cutting-edge machinery was created for the process with the fewest nodes possible. Fabs always strive to be ahead of the curve, so they invest resources in those cutting-edge processes, while machines for older processes lose value.

TSMC is at such scale that they can keep depreciated equipment and facilities and continue using them, as they have some clever ways to squeeze cash out of these fully depreciated facilities.

However, mature nodes typically do not fit into margin structures for businesses like Intel and GlobalFoundries. American businesses typically sell their outdated equipment and facilities to Chinese customers.  ,

One can see why. Operating a modern factory costs a lot of money. A reasonably sized fab might cost around US$ 5 billion in capital expenditures, which requires generating$ 50-$ 70 in revenue per second to achieve a 20 % return at the outset.

Even after it depreciates, it still needs to generate between$ 30 and$ 40. Producing a chip at 65 nm would require the output of a large wafer every 30 to 60 seconds, which would be a significant challenge.

SMIC and China’s Strategy ,

The primary motivation behind China’s semiconductor strategy is domestic self-sufficiency, which sees semiconductors as a crucial national asset comparable to its strategic oil or food reserves.

The secondary objective is to create a potential chokepoint that increases their geopolitical leverage by establishing a strategic leverage point in the global supply chain through the use of mature node chips.

The Chinese simply do not face the same economic constraints that we do in achieving these goals:

- State funding and affordable loans lessen the scope of the issue of capital expenditures. The terms of the loans are negotiated, but the expectation is that they will be paid back.

- Profits are not as important, given that the stakeholders are the state, which has a different set of priorities.  ,

- R&D is carried out for them. They are buying mostly used or old equipment ( from the West ).  ,

The very deliberate Chinese economic strategy, which involves strategic industries being pushed forward with a blank check, is the one that cannot be stressed enough.

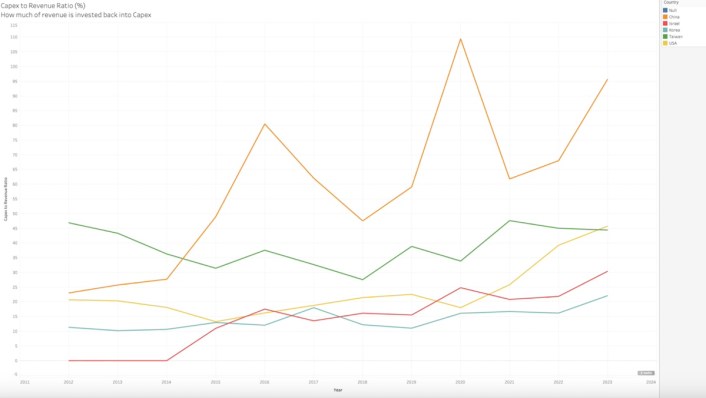

The graph below shows the capex- to- revenue ratio in the domestic semiconductor industry. To advance their chip industry, the Chinese are going deep into the red with capex spend.  ,

SMIC wants to expand into more developed nodes, but at the moment it’s a struggle. SMIC strikes a balance between using the outdated Western equipment they still have access to and creating their own indigenous Chinese ecosystem, which is largely just copied from the same Western equipment.

And even if they did have access to the best Western equipment, they would not have the know- how to make it work for them.  ,

In the meantime, they are indeed swamping the mature node market. Even though the margins for individual mature node chips may be low, it sustains the business and achieves the strategic goal of creating a chokepoint.  ,

This deliberate” swamping”, and you can just read it in Xi’s speech” Major Issues Concerning China’s Strategies for Mid- to- Long- Term Economic and Social Development”, needs to be taken seriously.  ,

CHIPS Act as a response strategy

The CHIPS Act is essential in getting the US on the right path in terms of domestic chip production. Low-node chips should not be completely disregarded by us.

They are extremely important in light of the real danger of TSMC being lost. However, the Act does n’t sufficiently address the balance needed in light of the aggressive Chinese strategy.

Returning to the military supply chain, where China accounts for 20 to 40 % of the chips used in our systems. It is impossible to identify the origin of a chip, such as a generic microcontroller, due to the sheer volume of components in military hardware.

This is concerning, especially since some of these chips might originate from firms linked to the Chinese military, posing risks of side- channel and encryption attacks.

Domestic and foreign companies can increase their capacity for fabrication in the United States through loans, grants, and subsidies provided by the CHIPS Act. Despite initial doubts that NIST or the Department of Congress could get anything done, the program appears to be working.

One thing is missing, however: Mature nodes. Only$ 2 billion has currently been allocated in grants for mature nodes, and somewhere between$ 8 and$ 10 billion will eventually be set aside for it. Most of the money will go into leading- edge chips.  ,

Although I’m not overly cynical, the fact that Intel and GlobalFoundries were undoubtedly involved in the legislation’s development should explain the situation somewhat.

It’s challenging to explain how the economics of mature nodes work in facilities that do n’t have incredible amounts of capacity or completely depreciated equipment, and if it makes more sense if the facility is new.  ,

I’m all for public- private cooperation in designing economic policy and one might argue that friendshoring or pushing mature nodes when US capacity is already up and running might be a better strategy.

If the Chinese were not acting so purposefully, those claims would be much more persuasive. To respond effectively, we must become more aggressive.  ,

defensive and offensive options

We can both use offensive and defensive force to address the issue. I’d recommend doing both in conjunction. The first two are table stakes, in fact. They’d be described as defensive behaviors.  ,

- More money needs to be allocated to mature node chips.  ,

- We need to become far more aggressive about supply chain monitoring for military chips.

The third two are probably more agonizing. They’d be considered offensive actions, I suppose.  ,

- Chinese chips of all node sizes must be subject to a more comprehensive tariff regime.  ,

- We have sanctioned equipment for leading- edge nodes, but we need to push this further, even into software tools like Cadence and Synopsys.  ,

I do not think the first two in isolation will be sufficient, if only because in a race to the bottom on price, we will never win, especially as we are ramping up domestic production or figuring out friendshoring for chips.  ,

The third is not particularly attractive, but they will ease the pressure on the domestic chip industry to increase. More than that, it will put financial pressure on SMIC.  ,

The fourth is undoubtedly unpopular and the most aggressive. Applied Materials makes about 45 % of its revenue from China. It will be very painful for us to leave that market, and we will have to make up for it.

Critics will say that if we cut them off, they will eventually create their own domestic rivals, which is accurate, but like tariffs, they are just a blunt tool to slow China down so that we can increase our domestic capacity.

Chips are just one aspect of a larger economic and geopolitical battle we’ve been playing with China for the last two decades. We’ve been sucked into a backseat out of naivete or lack of resolve, but we must at least change our tune.  ,

Steven Glinert is founder and CEO of the Sphere Semi semiconductor startup. Between Singapore and the Bay Area, he resides.  ,

This , slightly abridged article , was first published on Noah Smith’s Noahpinion , Substack and is republished with kind permission. Read the original and sign up as a Noahopinion subscriber  here.