In the midst of a developing martial ship-building competition with China, the US Navy hopes that 3D printers will maintain its ramped-up nuclear submarine generation schedule.

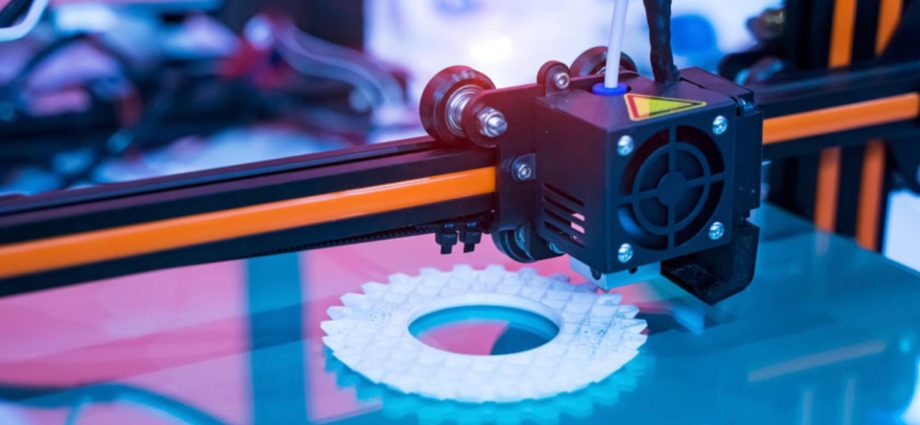

Defense News reported this month that the US Navy plans to 3D print a variety of metal parts as standard parts for installation on the new vessels in order to build the Virginia-class attack submarines ( SSN) and the Columbia class ballistic missile submarine ( SSBN ) on schedule.

The US Navy’s present limited use of 3D printers for smaller repair parts aboard ships will soon be replaced by common use in its submarine-industrial center, which is expected to increase output to its highest level in 40 years. This is being supported by the Antioxidant Manufacturing Center of Excellence in Danville, Virginia.

According to Defense News, the US Navy and the middle are working together to set up a system of 3D printers partners and an electronic order guide to manage the workload, along with 28 approved plans for different submarine parts.

The UK and Australia are partners in the AUKUS empire, which aims to establish a global community of more than 50 locations to 3D-print material components for new submarines. According to the Defense News statement, it also intends to release a modern order guide in 2024 with at least 15 3D printing partners that will produce between 150 and 200 components.

As the US Navy strives to achieve a submarine design price not seen since the 1980s, the switch from anad impromptu to widespread use of 3D printing technology will be difficult. According to experts cited in the Defense News review, the technology must be sophisticated enough to meet stringent production standards, noting important certification and qualification requirements.

Some companies use cameras and sensors to track their 3D printers process and spot flaws in real time, reducing the frequency of end-of-production assessment to one in 100 things, in order to maintain quality control.

The US Navy is urging politicians to review the increased use of 3D printers so that it can create three ships annually, according to a report by Defense One from last month. According to Defense One, Rear Adm. Jonathan Rucker, the US Navy’s top client for attack submarines, additive manufacturing is crucial for adhering to construction schedules and preserving new submarine operation.

The US Navy plans to increase production to one Columbia course and two Virginia school ships annually, according to the source, and the first 3D-printed parts are already being installed. It mentions that the US Navy is asking for more money, with the White House suggesting$ 3.4 billion for the creation of technologies like additive manufacturing and part tests.

The US Navy’s ability to meet operating needs is being hampered by problems with underwater production. A condition of 66 to 72 Addresses to hinder and fight enemies, specifically China, was mentioned in the Biden administration’s shipping plan for the fiscal year 2022. There are now only 49 ships in the US Navy, and their operational rates are dubious.

Emma Salisbury mentions in a War on The Stones article from last month that after 1992, the US underwater business base’s production declined significantly due to an abrupt decline in demand after the Seawolf SSN programme was terminated at the end of the Cold War.

She points out that there are now fewer production sites because Electric Boat and Newport News, two renowned US underwater builders, closed their off-site construction and machining facilities. According to Salisbury, the reduction in lively suppliers in the submarine industry and shipyards was caused by challenges in finding and keeping skilled workers.

According to a Defense News statement, from about 17, 000 manufacturers to simply 5, 000 today, the industrial center of businesses supplying US underwater output has decreased by more than 70 % since the 1980s. According to  , the US Navy started producing one Virginia-class underwater annually as late as 2013, but by governmental 2026, it intends to produce five times as many.

According to a USNI report from March 2023, it will take Electric Boat and Newport News five years to be able to consistently deliver two Virginia-class attack boats annually, with the two shipyards now on track to produce about 1.2 boats annually.

Submarine upkeep emphasizes the manufacturing difficulty. Less than one-third of US Navy SSNs have completed repair on schedule over the past ten years, according to a report released in September 2022.

According to the report, the earliest Virginia-class boats are the most challenging to repair on schedule, with the group returning to service nearly nine months later than anticipated. The Los Angeles-class boats, in contrast, require four and a half months to complete inspection, according to the document.

China is also making steady progress in both quality and quantity with its submarine software. The US Navy already employs 71 ships, a fleet of 53 SSN, 14 SSBN, and four SGNs that are entirely powered by nuclear energy. China, in contrast, had 44 conventional attack submarines ( SSKs ), 6 SSNs, and 6 SSBNs as of March 2023.

According to a report from the US Congressional Research Service ( CRS ) released last month, China is modernizing its submarine fleet with newer models, such as the Type 095 cruise missile submarine ( SSGN ) and Class 096SSBN. Both are apparently getting close to the increased Akula I class SSN in Russia in terms of propulsion, quieting, sensors, and weaponry.

According to the CRS statement, increased cooperation with Russia may help China’s efforts to modernize and enhance its submarine army, including known engine and noise reduction weaknesses.

According to a recent briefing slide from The Warzone, China is currently 200 times more capable of producing surface warships and submarines than the US. The US Office of Naval Intelligence ( ONI ) has highlighted this significant gap in US and Chinese shipbuilding.

The quotes from the ONI slide show that by 2035, the difference between China and the US will be considerably wider.