Developed and developing countries have been escalating the use of industrial policy through subsidies, trade restrictions and other instruments to secure the supply of transition-critical minerals and rare earths essential for developing low-carbon technologies and the move to green energy.

But these policies have created uncertainties and their impact on the green transition needs careful assessment.

Achieving net zero carbon emissions will require an estimated seven-fold increase in demand for transition-critical minerals between 2021 and 2040. Currently, the United States and the European Union import 80% and 98% of their critical mineral needs respectively, while Japan imports 90%.

Given these dependencies, there are heightened concerns around access to the supply of transition-critical minerals, especially given the concentration of supplies in China.

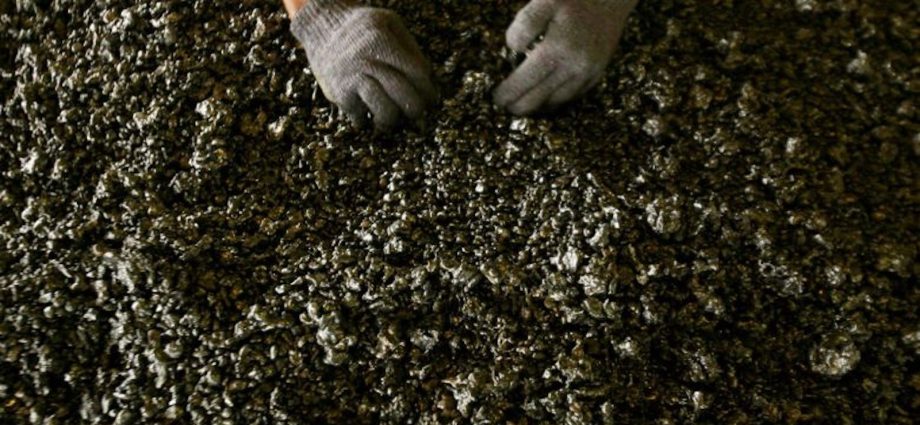

While the extraction of critical minerals is dominated by Chile and Peru for copper, Indonesia, the Philippines and Australia for nickel, the Democratic Republic of the Congo for cobalt and Australia for lithium, China is the leading processor.

To reduce dependency on these concentrated supplies of transition-critical minerals, developed countries have introduced industrial policies such as reshoring the sourcing of transition-critical minerals and the production of low-carbon technologies.

In the United States, the Inflation Reduction Act provides subsidies of US$7,500 for electric vehicle (EV) purchases as long as the components, such as batteries, are produced in the United States or in allied countries that have a free trade agreement (FTA) with the United States.

This has led to Japan signing a limited FTA with the United States on minerals so it can provide components that qualify for the subsidy. The European Union, Indonesia and the Philippines have also approached the United States for similar limited trade agreements.

The European Union has proposed legislation – the Critical Raw Materials Act – which requires members to reduce their dependence on China for critical minerals from 80% to 65%, with a target to increase supply from within the European Union to 10%.

Since 2020, Japan has also introduced a range of industrial policies to incentivize the relocation of Japanese-owned facilities from China to ASEAN and other countries.

In May 2022, Japan introduced the Economic Security Promotion Act, which aims to secure supply chains for critical minerals and support the development of critical and emerging technologies.

Industrial policy targeted at onshoring or building supply chains with allies is unlikely to reshape the industrial geography of critical minerals any time soon.

The investments required to uproot supply chains face uncertainty from increased demand, shifting industrial policy and geopolitics, and long lead times, as well as limits from relying only on supply from “allies.”

Even if onshore extraction could be increased in developed countries, pushback on environmental concerns is likely to hamper progress. Meanwhile, industrial policy has the potential to disrupt or raise the cost of access to critical minerals and transition technologies, especially for developing countries.

The better policy response is not onshoring or creating strategic alliances. Expanding and diversifying investment in resource-rich developing countries would increase and diversify supply, reducing reliance on a few countries and firms. China must be accommodated in the interim given its significant role in reducing the cost of decarbonization in other countries.

Diversifying investments to resource-rich developing countries also has its challenges, as industrial policy intended to increase the value-add of mineral resources can distort investment decisions.

Fiscal constraints mean that subsidies are not an option, so policies have come in the form of restricting raw materials exports, linking mining concessions with phased-in downstreaming and local content requirements.

Indonesia, for instance, passed a law in 2009 restricting exports of unprocessed minerals and requiring mining concessions to build smelters by a given deadline.

In the case of nickel, Indonesia has the largest reserves in the world and accounts for 22% of exports. In 2014 Indonesia banned the export of nickel ore. The policy has been deemed a success, with exports of ferronickel and stainless steel increasing from $2.2 billion in 2014 to $29 billion in 2022.

This led to increased investment from China and nickel mining companies such as Vale, spurring economic growth in east Indonesia. With ample supplies of nickel, copper and graphite, Indonesia has ambitions to become a supply hub for EVs and batteries.

The costs and benefits of export restrictions as a means of increasing value-add are, however, problematic.

Value-add is not just the increase in exports of the final product, or even jobs growth – which is low given the capital-intensive nature of the industry – but the difference between the cost of production and cost of materials, including the cost of building infrastructure and meeting energy needs and revenues forgone as other suppliers expand market share for unprocessed ore.

Success in expanding nickel production might not be repeated with other commodities where Indonesia is not a major producer or where substitutes are readily available. And other minerals may not attract investments in the way that nickel did.

To ensure that further downstreaming leads to value-added industrial development, complementary policies such as building infrastructure, access to clean energy and human capital development will be necessary.

As the search for lithium to make EV batteries shows, it is not enough to be rich in one resource. Keeping trade open and predictable is as vital to resource-rich countries as it is to resource-poor economies. It is also essential for the diversification of refining and processing capacity to reduce dependence on single suppliers.

Mari Pangestu is Professor of International Economics at the University of Indonesia. She is former World Bank Managing Director of Development Policy and Partnerships.

This article was originally published by East Asia Forum and is republished under a Creative Commons license.