SINGAPORE: From bagless and cordless vacuum cleaners to bladeless fans, Dyson wants to make daily chores and routine tasks easier.

But bringing ideas from conceptualisation to production typically takes years, with engineers making changes to prototype after prototype.

Dyson’s bagless vacuum cleaner, for example, took no fewer than 5,127 prototypes over five years. The company’s foray into beauty products with its hair dryer involved 600 prototypes across four years.

“Usually, it’s a long process,” Mr Brian Hu, a senior electronics manager at Dyson Singapore, told CNA.

The 39-year-old has designed and developed electronics hardware for a range of Dyson products, such as the bladeless fan and cordless vacuum, over the past 12 years.

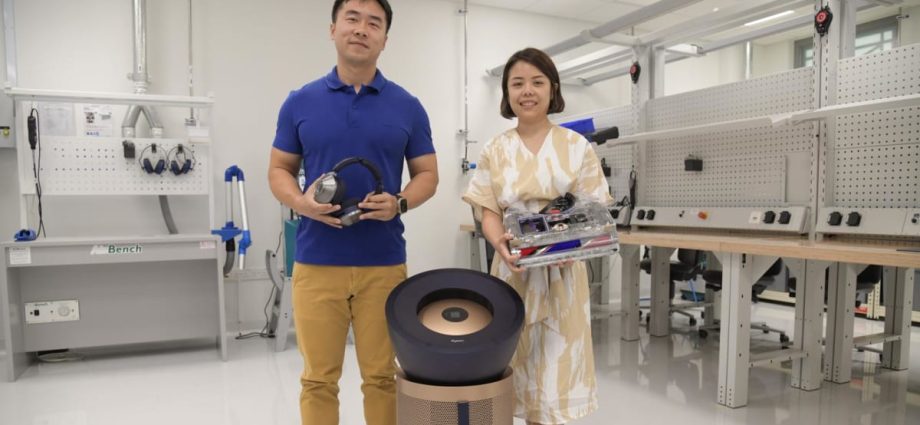

The latest project that Mr Hu, who leads a team of 36 engineers in Singapore and Malaysia, spent a year working on is the Big+Quiet air purifier, one of six new products Dyson launched this month.

Mr Hu and his team worked on modifying the motor driver circuit to reduce the noise that typically comes with bigger air purifiers on the market.

The engineers also had to think about how “to make the invisible visible”, so as to allow users to monitor indoor air quality through an LCD screen or the Dyson app.

“We have to utilise many sensor chips to capture (data about the particles in the air) and make sure that is processed correctly, pushed into the cloud and displayed,” Mr Hu added.

This has to be done in coordination with other engineering teams overlooking aspects such as software and technology development – most of which were located in different time zones.

But the satisfaction of overcoming challenges is also immense.

“It’s like watching your own baby being born,” he said with a laugh.