After a slow start, India is beginning to realize its potential as a promising market for industrial robots and as a developer of robot technology.

According to International Federation of Robotics (IFR) data, industrial robot installations in India increased by 54% in 2021 to 4,945 units. This put India in 10th place worldwide, behind Mexico but ahead of Canada, Thailand, Singapore and Spain. Data for 2022 is not yet available.

The auto industry is the largest buyer of industrial robots in India, accounting for 31% of total installations in 2021. Other large user industries include metals and machinery, plastics and chemicals, electrical and electronic equipment, and pharmaceuticals and food.

In a May 3 statement, IFR President Marina Bill noted that “India is one of the world’s fastest-growing industrial economies. Within five years, the operational stock of industrial robots has more than doubled to reach 33,220 units in 2021. This corresponds to an average annual growth rate of 16% since 2016.”

Since the “Make in India” program was launched by Prime Minister Modi in 2014, the operational stock of industrial robots in India has tripled. But it is still a drop in the bucket compared with the 1.2 million units installed in China and nearly 400,000 units in Japan.

China, long known as the “world’s factory” as Western economies shipped manufacturing off-shore, is so far ahead of other countries in the deployment of industrial robots that comparisons are almost meaningless. In 2021, more industrial robots were installed in China (268,000) than in the rest of the world combined (249,000).

Japan ranked second (47,000), followed by the US in third (35,000), South Korea (31,000), Germany (24,000) and Italy (14,000). Realistically speaking, India should be able to triple its annual installations and catch up with Italy and then Germany in the near-term future.

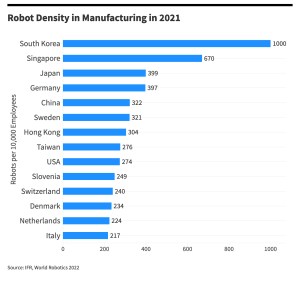

China also ranks high in industrial robot density as measured by the number of robots per 10,000 employees in manufacturing. In 2021, mainland China ranked fifth after South Korea, Singapore, Japan and Germany. Hong Kong and Taiwan ranked seventh and eighth Sweden was sixth. The US ranked ninth, down from seventh the previous year.

The robot density in India’s auto industry was 148 robots per 10,000 employees in 2021. The figure for China’s auto industry was 772, compared with 332 for all Chinese manufacturing. The scope of the challenge and the opportunity for India are both evident.

South Korea set a record high of 1,000 robots per 10,000 manufacturing employees in 2021. This was a function of the country’s large and technologically advanced electronics and auto industries.

The figure for Singapore, which has a concentration of advanced industries, was 670. The figures for Japan and Germany, which have much broader industrial bases, were 399 and 397. In the US, the figure was 274.

As is the case in China, the largest industrial robot vendors in India today are the world leaders: Fanuc, Yaskawa and other Japanese companies as well as Universal Robots, ABB and Kuka. Universal Robots is a Danish company owned by Teradyne of the US. ABB is headquartered in Switzerland. Kuka is a German company owned by China’s Midea Group.

But there are numerous Indian robot companies – so many with outstanding characteristics that the top ten and other leading company lists published by various market research companies overlap but are not the same. Among those that appear on these lists and that illustrate the range of Indian robot manufacturing and technologies are:

- Precision Automation & Robotics India (Wipro PARI), a large integrated industrial robot and factory automation systems supplier headquartered in Pune, Maharashtra, with operations in India, Europe and the US.

- Hi-Tech Robotic Systemz, a supplier of autonomous mobile robots used in factories and warehouses headquartered in Gurgaon, Haryana. It also supplies autonomous and driver assist systems to rationalize and improve safety in industrial vehicle fleet management on public roads.

- Gridbots, a manufacturer of industrial, military, space and nuclear power plant robotics, driverless military vehicles and machine vision inspection systems headquartered in Ahmedabad, Gujarat.

- Asimov Robotics, a provider of robotics hardware, software and robotics consulting services headquartered in Kochi, Kerala. Focused on medical and healthcare with particular expertise in autonomous transport between patients in intensive care/isolation and clinical labs. It also serves R&D and implementation projects in surgery, space and defense, and makes service robots used in hazardous and other challenging environments.

- DiFACTO Robotics, a worldwide supplier of industrial robots and other factory automation equipment and services headquartered in Bengaluru (Bangalore), Karnataka.

- Systematics, headquartered in Bengaluru, the first company to completely design and produce collaborative robots (cobots) in India. Products include 6-axis robotic arms that can share workspace with humans without a safety fence.

- Invento Robotics, a producer of humanoid service robots for retail, bank office, healthcare, events and other applications using speech recognition, face recognition, indoor navigation and fleet management algorithms.

- MCI Robotics, a designer and producer of materials handling, assembly, welding, grinding, milling, polishing, painting, sealing and dispensing robots headquartered in Chennai, Tamil Nadu.

- CynLr (Cybernetics Laboratory), a provider of machine-vision technology based on machine learning that enables assembly, logistics and other robots to identify and handle objects without training.

Tracxn Technologies Limited, a global start-up data platform headquartered in Bengaluru that works with venture capital and other finance companies worldwide, has identified 47 industrial robotics start-ups in India. Given the country’s high educational standard, industrial momentum and entrepreneurial bent, there are bound to be a lot more in the future.

The All India Council for Robotics & Automation (AICRA) is a not-for-profit organization dedicated to making India a leader in robotics, the internet of things (IoT), and artificial intelligence (AI). It provides technical and other assistance to its more than 3,500 member organizations and professionals. AICRA’s mission statement is:

- Upgrade Robotics, IOT and AI skills to international standards through significant industry involvement and develop necessary frameworks for standards, curriculum and quality assurance.

- Enhance, support and coordinate private sector initiatives for technical skill development through appropriate engagement models; strive for significant operational and marketing involvement.

- Play the role of a “market-maker” by bringing financing, particularly in sectors where market mechanisms are ineffective or missing.

- Establish India as a hub for innovation, products and technology start-ups.

- Be an industry platform for sharing and building best practices and collaborative engagement.

AICRA has established Technology Governance Steering Committees (TGSCs) for defense, healthcare, agriculture, startup, education and aerospace. It has also signed an MoU with the Chandigarh Group of Colleges (CGC) in Punjab to establish an Industry 4.0 Center of Excellence to provide students with ideas, learning materials, training and hands-on experience in robotic process automation, robot operating system (ROS) open-source software and other technology.

The All India Robotics Association (AIRA) is a not-for-profit organization established to develop and support robotics ventures in areas including regulatory approvals, funding, imports of electronic components, production technologies and skill development.

AIRA aims to create the ecosystem required to make India a global hub for robotic production and technology.

That is a project for the next two decades years, one that is likely to change India and the world economy beyond recognition.

Follow this writer on Twitter: @ScottFo83517667